That looks amazing!

That looks amazing!

Was more a thought about if you are concerned about micro fibre particulate (what I took from your post, sorry if I misunderstood) plastic on plastic or plastic on metal are fine for sure, maybe a little exaggerated. Do wonder though about the wear of 3d printed bushings, surfaces won’t be smooth, some of the glass filled nylon I’ve used has almost a soft surface to it, it’s really hard to describe, some post processing though would probably make my (mild) concern moot though so.

Wrt composites hobbyist/prosumer grade manufacturers (some that target engineering customers in that bucket too) claim they don’t experience the same warping or shrinkage in general, whether or not that’s true I don’t have enough information to tell you unfortunately. Have found both common types definitely have more rigidity, I use them in places where that really matters.

It’s pretty common to see cheap bearings in 3d printed parts, actually mildly interesting to me that bushings don’t seem to be, at least at the hobbyist level. To go further, how many designs do you see with heat set inserts or pressed in nuts?

Shit just even for filament printing, there’s some solvents that get thrown around online that yeah, you really shouldn’t use in a home setting, it’s really easy to get things like MEK, which work, but starting to get into nasty territory for stuff that will dissolve filament.

Most people do not have adequate ppe or ventilation to deal with chemicals at home, or a fire cabinet, or even know how to find an SDS.

Semi related, lithium batteries are straight up terrifying, primary cells more than rechargeables, but same idea, I honestly hope no one ever gets to experience an actual full on cell failure, I avoided them thankfully but heard stories of just how much energy is released in even one C or D sized cell going.

On the composite filaments, abrasive filament sure sounds like a great thing to make wear surfaces out of! There’s a list if things that idk if I’d print, and that’d be up there, ots oil bronze bushings are like, a buck, maybe 2? And they’ll last a hell of a lot longer.

1.0 drops right when I actually have time to take vacation, scratches the same itch as some of the old Minecraft mod packs (so does factorio, I just really like building factories lol) I just really love watching things whip around.

SW was great to use back in uni but holy hell is it full of phone home stuff and really annoying these days, I scrapped my license, they straight up wouldn’t let me cancel within 30 days of renewal so I yanked my cc and “cancelled” that way.

Use FreeCAD, mentioned in a few posts, it’s got some clunk but it’s 100% useable, has more than enough features for prosumer/hobbyist use, personally I’d make an argument it’s fine for enterprise use too, Ondsel seems to think so considering that’s the market they’re targeting with their releases. I’d recommend the Ondsel release or Realthunder’s (what I currently use) which has features/fixes that will be merged back, and 100% look at mainline freecad when the 1.0 release drops

First and foremost, I don’t know your circumstances but I can relate and I’m sorry. Your worth isn’t measured by “productivity” or “what you amount to”, you matter. Work Culture and general North American society isn’t great for us with ADHD, all we can do is try our best. I swear to you that even when things look dark and there’s no way out, it does end. I’m going to put a ramble of my experience in a spoiler.

My ADHD got me into a pit of credit card debt, small compared to others at just under $19k CAD but I still had $20k+ in my student loan and I couldn’t see a way out, struggled hard, kept deferring payments and hitting overdraft, legit at my worst point I was $20 from bankruptcy, I probably could have got support from family and my at the time girlfriend (now partner) but I was too ashamed of it, I didn’t want to admit it to my partner (and she knew it, I don’t lie well, not that that’s a skill I really want to have). It put a lot of strain on my relationship, made me the most anxious I’ve ever been and very nearly ended my relationship, my life was on the verge of falling apart completely, I’d be lying if I didn’t have the exact same thoughts.

I was diagnosed 3 years ago at 31, I did what my dad (who’s likely got ADHD if not AuDHD, but won’t get evaluated) did and expended all my energy on work to the detriment of other parts of my life, I also struggled with binging (spending is obvious, but also alcohol and food) and emotional regulation.

My partner is the reason I got evaluated, she convinced me to get into therapy (I have a good therapist who has ADHD, didn’t know that when I found them). After diagnosis, it took me at least a year to begin accepting that I have ADHD (funny that putting a name to it changes things right), that it effects everything I do and that I have, and will always have it. Hardest thing was realising just his much of my personality is influenced by it. Medication is helpful but it’s not perfect, but with therapy, it’s helped address some of the maladaptive coping mechanisms I developed.

If you have access to therapy and aren’t already, it helped me immensely. Depending where you live there may be resources you can access through your health authority. We’re here if you want, even just venting can be helpful.

Not just was Netscape, Mozilla was straight up founded by Netscape people https://en.m.wikipedia.org/wiki/Mozilla

On January 23, 1998, Netscape announced that its Netscape Communicator browser software would be free, and that its source code would also be free.[4] One day later, Jamie Zawinski of Netscape registered mozilla.org.[5] The project took its name, “Mozilla”, from the original code name of the Netscape Navigator browser—a portmanteau of “Mosaic and Godzilla”,[6] and used to coordinate the development of the Mozilla Application Suite, the free software version of Netscape’s internet software, Netscape Communicator.[7][8] Zawinski said he arrived at the name “Mozilla” at a Netscape staff meeting.[9] A small group of Netscape employees were tasked with coordinating the new community.

Do you have an iPhone or any phone with lidar built in? It’s been a while but I recall it being an option for scanning, make use of tools you already have. I’m not sure what exists for Foss related apps though sorry, and afaik they’re not super accurate (dedicated scanners can get <0.01mm resolution from what I’ve seen but they’re expensive) but if your goal is layout that’d do the trick in my view. Heck, as you said, camera scanning would work, there’ll be cleanup but should be good enough to get you dimensions.

Another thought, could check with local makerspaces or the like, totally possible they may have scanners you could use, or could put you on the right track. Diy wise, kinects as mentioned, I’m not experienced with these but there are photogrammetry tools, micmac could work, there’s meshroom but that needs some compute hardware and COLMAP could also be worth looking into

Edit: Photogrammetry is decently accurate afaik, recall sitting in a tech meeting at my last job where the process engineers from the material handling department presented a poc they did with some cheap drones and cheap cameras, they did a fly over of the pier to scan ore piles and apparently were able to get fairly accurate weight estimates from the photogrammetry results, which was really cool to me.

Could use Polars, afaik it supports streaming from CSVs too, and frankly the syntax is so much nicer than pandas coming from spark land.

Do you need to persist? What are you doing with them? A really common pattern for analytics is landing those in something like Parquet, Delta, less frequently seen Avro or ORC and then working right off that. If they don’t change, it’s an option. 100 gigs of CSVs will take some time to write to a database depending on resources, tools, db flavour, tbf writing into a compressed format takes time too, but saves you managing databases (unless you want to, just presenting some alternates)

Could look at a document db, again, will take time to ingest and index, but definitely another tool, I’ve touched elastic and stood up mongo before, but Solr is around and built on top of lucene which I knew elastic was but apparently so is mongo.

Edit: searchable? I’d look into a document db, it’s quite literally what they’re meant for, all of those I mentioned are used for enterprise search.

Postgres runs well in a container in my experience and is nice to work with, def support that. I know sqlite works well, but nice to have a system sometimes.

If you live near a microcenter

I’m like a stone’s throw from the border, if they’re cheaper very much consider crossing for that (closest looks like Detroit though, wrong crossing :/) at least for the tap carriage and mount.

Layer lines are unavoidable imo, I’ve sorta just come to terms, I think I run a tad hot and haven’t fully tuned my profiles, but happy with it for my purposes, and definitely heat soak as well, got a process where I do it right after plate prep/cleanup, then I go do my plating and slicing, gives lots of time.

LEDs I’m mixed on, I moved my gantry cam because they seemingly were aimed right at it and you couldn’t see anything. I keep thinking about a nozzle camera, but with my current setup I really don’t feel like running another umbilical and I’m not 100% sold that it’d survive or really be that handy.

How is the rapido? I’m using dragon HF/UHF for spares and using my existing v6 nozzles, have heard the rapido has some good results.

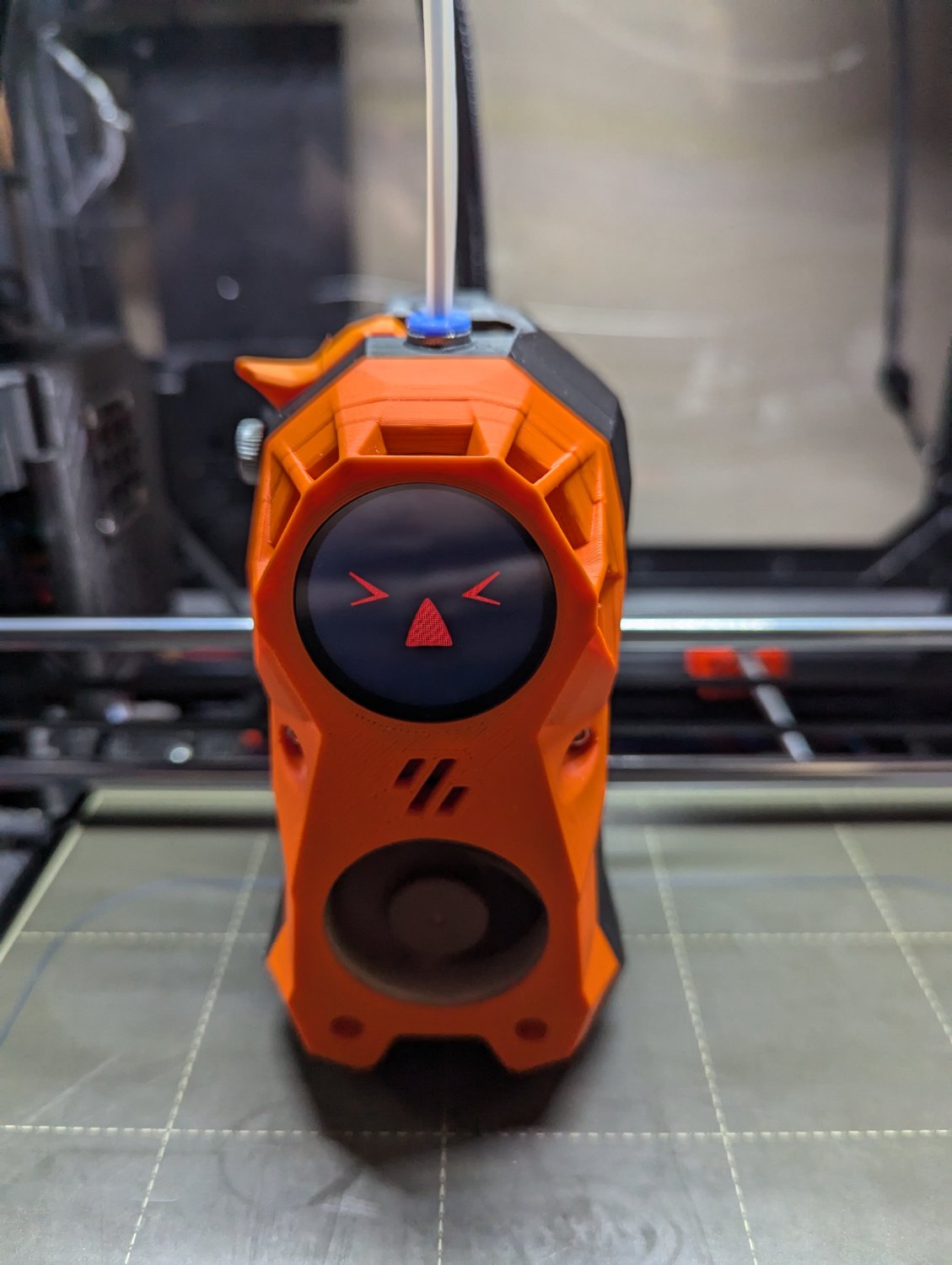

Are those machined idler blocks‽ if not you have some really solid prints! Impressed with how clean everything is! Just took a shopvac to mine friday, printing parts for a Stealthmax, so lots of buildup.

Need to get into that good enough mindset, definitely caused myself some headache (grabbed a Knomi for the heck of it, tons of interference issues with the blowers I use (sunon and gdstime) but got it going on the fanken-prusa

Instead of running LEDs to the toolhead. It’s cheesy and heavy, but rule of cool right?

If you don’t feel like printing parts, could run the usb umbilical through the chains.

Is your other printer still up? Having a backup has come in really handy.

At least Calgary gets chinooks (as much as they suck for migraines) for a mild reprieve

My understanding is that medicated were not found to have the same increase in risk.

Fair enough, visually the ModernUI made it similar to what I was used to, I pretty much bounce between part design, sketch and assembly workbenches for everything I do, been a bit but I think ondsel swaps automatically to sketch from part workbench and the dimension tool is way nicer, general freecad doesn’t really have that smart dim tool, but the keyboard shortcuts make it better.

Workflow wise, I found it pretty much exactly the same as I used SW and other parametric cad packages, make your sketches, extrude your base and then build sketches for other features. Toponaming fix seems to make external geometry references a bit more reliable, have a few cleanups if I change way back in the tree, not all sunshine and rainbows though, definitely had some frustrations and clunk. What’s sold me honestly is I dove in with a largish project (more than I expected tbh, I’ll post it when it’s more mature) and it’s so far totally met my needs.

That sucks! Seems to work on my oldish laptop, can’t recall if I used on my really old one too but they both have 16gb of ram and running an appimage on Debian for those, windows seems to be happy with it. Running the python 3.11 versions as well, idk if that makes a difference

It’s an add-on ModernUI I really like it, configurable as well, mainly use for ribbon bar and dockable panels

from the github, I use small icons with no labels (like the window in the middle), works well for me on an ultrawide.

Seriously give Ondsel a try if you haven’t, has a different ui on top of freecad and a few workflow changes/sketch tools that make it less clunky. I use realthunder + modern ui for freecad and while yeah, there’s clunk, it’s useable and importantly, no limits on your files. Modern UI gives freecad a ribbon bar and some other enhancements that I like, swapping between benches took a bit to get used to, draft at least the hotkeys are kinda sorta intuitive and make the flow a lot nicer.

I switched cold turkey off of SW Maker for that reason, it limits where your files can be opened on that license, plus kept trying to save my files to a cloud storage by default. I’ve said it before, yeah freecad isn’t perfect, has clunk, but it’s provided to me free of charge with no limitations on its usage, I’ll gladly accept that.

Klipper will halt if a canbus toolhead disconnects anyhow, or at least how I have it configured it seems to, will handle packet loss just fine, outright disconnects? Nah, it wasn’t happy.

Klipper wise, imagine you could do something with the can uuid, I have a macro that I found that sets offset based on sheet (replicating prusa’s sheet selection in marlin, I like to have a bit less squish for nylon for example, more for textured sheets), offsets stored in a config file but you could easily swap that for an actual database if you wanted to.

There’s some klipper extensions like spoolman that are kinda sorta that for material management, yes relies on manual entry afaik, but supports material changes so presumably multi toolheads and more importantly, can share across printers, have it running on my server.

Don’t even get me going on patents…

With exchange it’s closer to $950 cad, best bang for your buck is probably used. Quick glance at kijiji and I saw some 3070tis for sub $400, heck if you’re fine with slightly older hardware just saw a ryzen 3700x + 2070 super, ram, full system honestly for $650 cad. You’ll probably get quite a bit of mileage out of that CPU, I ran with a 3rd gen i5 for nearly a decade